Image: PRnewsfoto – LS Power

According to professional research, many data centers have adopted lithium batteries as a backup energy source. Compared with lead-acid batteries,lithium batteries have the following unmatched technical advantages.

Perfect BMS design is the core technology of lithium battery system safety

Lead-acid battery manufacturers usually do not produce BMS (Battery Management System).

All lithium batteries are equipped with BMS as standard. When the battery has any over-voltage charging, over-current discharge, battery short-circuit, and other faults, the fault current can be quickly cut off by the BMS to prevent the risk of thermal runaway of the battery. It can be said that the BMS is the whole core technology of lithium battery system safety.

Lithium battery BMS not only monitors the voltage, current, and temperature of each battery cell in real-time but provides battery health trend analysis. More importantly, it can actively balance the charge and discharge of the battery cell, and ultimately improve the consistency of each battery cell. Failure of the entire battery pack caused by the barrel short-board effect. These are all lead-acid batteries BMS does not have.

The chemistry material of lithium battery

There are many schools of lithium batteries, such as lithium titanate, lithium cobalt oxide, lithium iron phosphate, lithium manganate, nickel cobalt manganese ternary lithium (NCM), nickel cobalt aluminum ternary lithium (NCA), etc., all of which refer to lithium For battery cathode materials, each chemical material has its suitable application scenarios.

For data center UPS, due to its short-time high-current discharge, large discharge power, long-term backup, and floating charge, and other application characteristics, lithium iron phosphate, lithium manganate, and NCM ternary lithium technology are more suitable.

In the lead-acid battery era, the lead-acid batteries used by UPS accounted for nearly 20% of the entire industry; but after entering the lithium battery era, the lithium batteries used by UPS only accounted for less than 2% of the entire lithium battery industry.

The major users of lithium batteries are still IT consumer electronics, electric vehicles, and ESS energy storage. Therefore, the direction of lithium battery technology in these industries directly determines the direction of UPS lithium batteries.

There are endless debates on the energy density and safety of ternary lithium and lithium iron phosphate in the market, but it is undeniable that these disputes are only limited to one aspect of the theoretical performance of lithium battery cathode materials. The safety of the lithium battery system requires comprehensive consideration of many factors such as negative electrode material, electrolyte, diaphragm material, cell shell packaging, battery module grouping, BMS, fuse protection, DC circuit breaker, manufacturing process level, and quality control.

The problems caused by lithium battery cathode materials are less than 10% of all lithium battery system problems. The choice of a UPS lithium battery should be a comprehensive trade-off of safety, energy density, and cost. Only a high-quality lithium battery system can be selected to obtain reliable quality assurance.

Compatibility test of lithium battery and UPS

UPS can use lead-acid batteries of various brands, but not for lithium batteries, because lithium batteries have their own BMS, which is an intelligent battery that has self-management and control capabilities and communicates with the UPS host. When the lithium battery is fully charged, it will automatically disconnect from the UPS charger. The traditional UPS software design may think this is a battery failure and issue an alarm.

Lithium batteries of different materials have different charging and discharging voltages, currents, and cut-off voltages. For example, the rated voltage of lithium iron phosphate batteries is 3.2V, while the ternary lithium battery is 3.8V.

Therefore, we must not simply say that UPS can be used with lithium batteries, but can only be said to be suitable for a certain brand of lithium batteries. Before using the lithium battery, the UPS needs to perform a rigorous matching test with it, and it is necessary to update the UPS firmware for this lithium battery.

The high-rate lithium battery used by the UPS can be charged and discharged with a high current in a short time. Correspondingly, the design of the UPS charger also needs to adapt to this change.

With the maturity and improvement of lithium battery technology and the increasing cost optimization, data center UPS will quickly complete the conversion from lead-acid batteries to lithium batteries, which will allow data center managers to re-plan the gray and white areas.

In the future, lithium batteries will not only serve as UPS short-term backup delays, but their powerful cyclic discharge performance will extend to more applications, such as using UPS+lithium batteries to achieve peak-shaving and valley-filling and profitability from peak-to-valley electricity price differences, and even energy storage is not ruled out. Let us wait and see the technological revolution that this new energy brings to the data center!

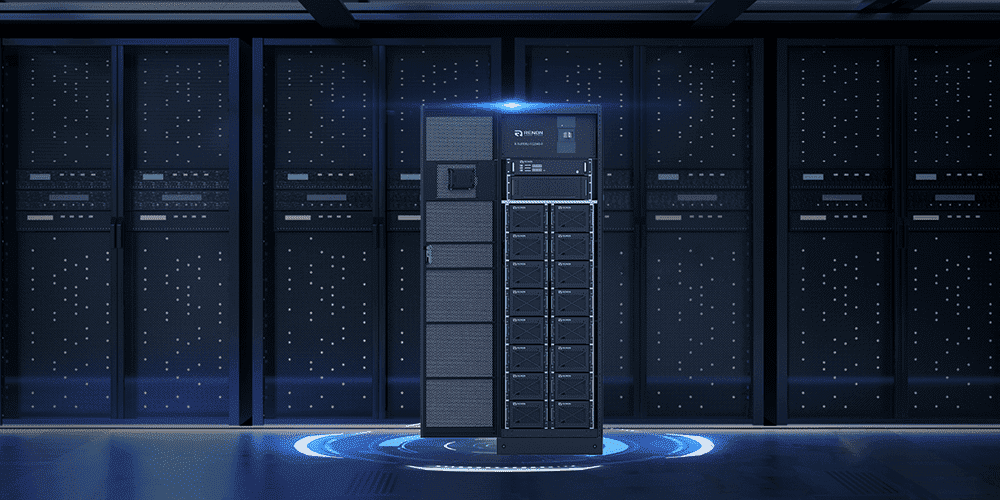

As an experienced manufacturer of lithium battery products, RENON has independent research and development capabilities and is committed to providing users with safe, lightweight, and long-lasting green energy products. We take the needs of customers first, and constantly adjust and optimize the design plan. We are also equipped with a professional manufacturing team and a strict quality inspection system, which can control the quality of the products in an all-round way. If you want to know more about related services, please contact us immediately!

扫码关注

We use cookies to understand how our audience uses our site.

Renon Power websites use cookies to deliver and improve the website experience. See our cookie policy for further details on how we use cookies. Privacy Policy